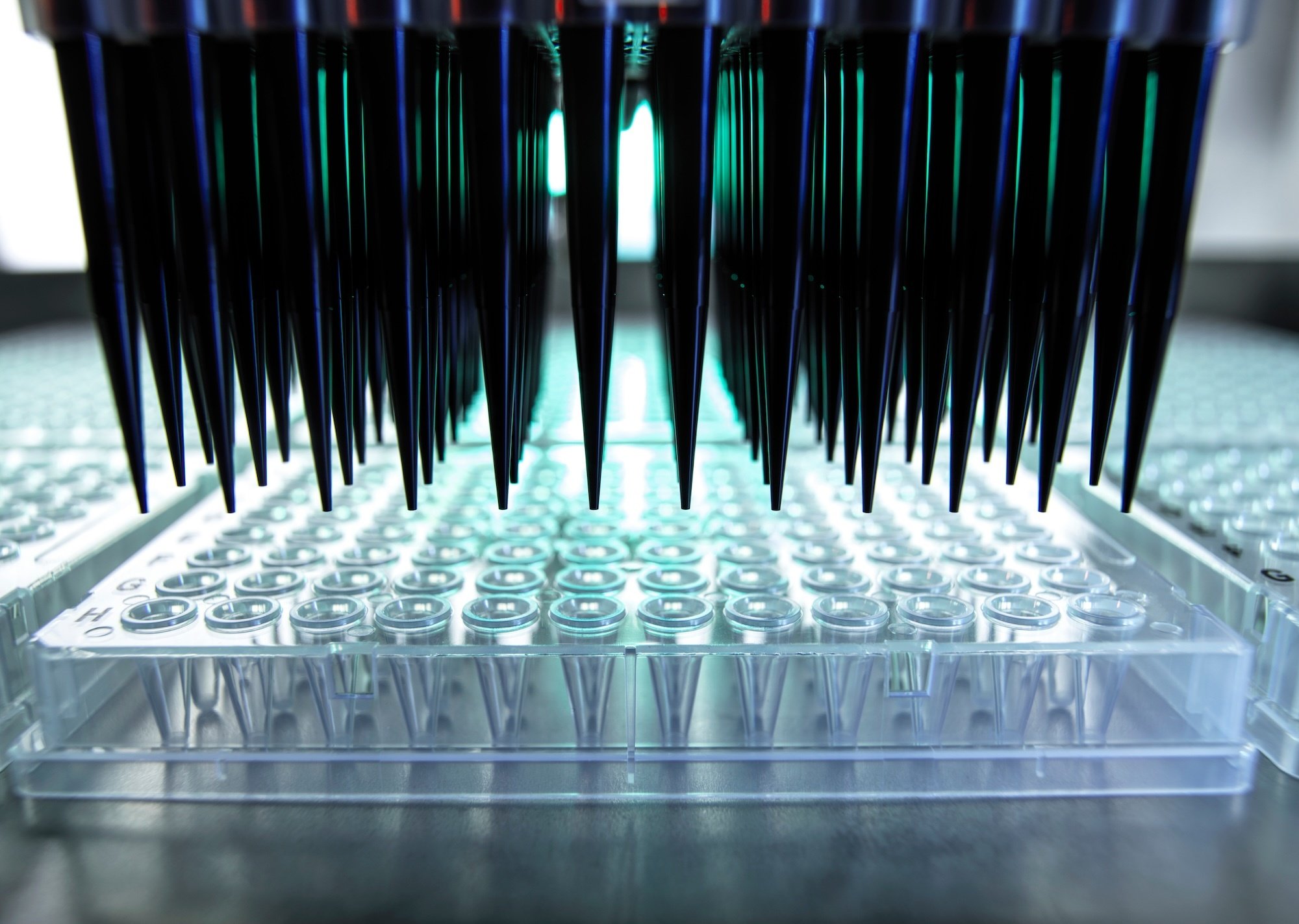

For decades, automation in life science labs has centered on instruments - liquid handlers, plate readers, sequencers. But a silent gap remained: what happens between those steps? Where are the samples stored, who moved them last, and are they even where they’re supposed to be? Sample handling - often overlooked, often manual - has become one of the most critical bottlenecks in modern lab operations.

The irony is hard to miss. Labs are investing in robotics and digitalization, yet thousands of valuable samples are still tracked via spreadsheets, labeled by hand, or retrieved from a freezer based on someone’s memory. The cost of this disconnect isn’t just inefficiency -it’s sample loss, mix-ups, and compromised data integrity.

That’s why the convergence of robotics and algorithmic orchestration is more than a technological trend. It’s a turning point. And it’s reshaping how labs of all sizes - from lean biotech startups to multinational pharma firms - manage the physical side of their digital science.

What Integration Really Means

In many labs, robotic systems are already present. Automated cold storage, robotic arms, even mobile lab assistants. But without integration, each of these components is an island - fast and accurate, yes, but blind to the bigger picture. A robot might know how to fetch a sample, but not why it matters, where it’s needed next, or whether the storage plan still makes sense given upcoming project changes.

That’s where advanced sample management platforms like Xavo come in.

The Xavo platform acts as a central nervous system, dynamically coordinating sample movement, storage, and usage across both human and machine actors. It continuously evaluates metadata, usage patterns, experimental timelines, and real-time lab conditions. Based on this, it makes informed decisions:

- Should a sample be moved to an active-access rack before tomorrow’s run?

- Is a vial being over-requested, putting its volume or integrity at risk?

- Are there long-dormant samples that could be archived or decommissioned?

- Can we re-optimize freezer layouts based on usage to reduce robotic travel time?

These aren’t just nice-to-haves. They’re the difference between reactive and proactive lab operations.

A Real-World Example

Imagine a high-throughput screening lab with multiple storage units and prep stations. Dozens of assay plates are being prepared each day. A robotic system can retrieve plates, but which plates? In which order? And what if the priority of one compound changes due to new data?

In a Xavo-integrated lab, the platform evaluates not just the static request queue, but also project urgency, compound stability, team workloads, and freezer availability. It can reshuffle tasks mid-run, route samples to the most available equipment, and notify lab staff only when human intervention is truly needed.

No more overhandling. No more missed windows. And no more chasing labels at 7:30 p.m.

Scale Without the Pain

For a biotech startup, this means achieving robust, traceable operations without building out massive operations teams. You don’t need a full-time freezer manager or a spreadsheet master - you need a platform that knows what’s where and why, and that works seamlessly with the robotic tools you’re already investing in.

For enterprise labs, the advantages multiply:

Centralized orchestration across geographies. Smart prioritization across therapeutic areas. Integration with MES, LIMS, and ELN systems. And perhaps most importantly - a dramatic reduction in avoidable manual errors that delay development timelines.

Why Now?

The cost of integrating robotics and AI used to be prohibitive. It meant custom software, hardware lock-ins, and months of consulting. Not anymore.

Xavo’s platform is cloud-native, hardware-agnostic, and built for modular growth. Whether you start with a single robot or a fully automated warehouse, the system scales with you - and learns as it goes. No rewrites. No disruptions. Just smoother, smarter sample logistics. And the quickest way to ROI!

Conclusion:

Sample handling isn’t just a background process. It’s the connective tissue of your lab. When it’s intelligent and automated, everything moves faster - and nothing gets lost along the way. With robotics doing the heavy lifting and smart algorithms doing the thinking, your lab becomes more than efficient. It becomes responsive. Predictive. Scalable.

That’s the Xavo promise: superior sample handling, driven by smart algorithms, integrated with the machines that move your science forward.

Ready to see it in action?